This post is also available in: ![]() English

English ![]() Français (French)

Français (French)

Introduction

As we have seen in a previous post, the carbon dioxide molecule (or CO2) plays a major role to enhance yields of biological processes, such as algae production and crop cultivation in greenhouses.

In fact, the special feature of the autotrophic metabolism of chlorophyll plant cells is their ability to synthesize organic matter in the form of carbohydrates from mineral matter (CO2, H2O and mineral salts). This phenomenon is known as the photosynthesis. Other living things can do it, like cyanobacteria, a group of photosynthetic bacteria commonly called algae. An article on the blog is dedicated on spirulina cultivation in a greenhouse.

In a greenhouse, CO2 consumption depends of the type of crops cultivated (photosynthetic activity). What is more, it also depends on how lighting is controlled: 12-month lighting means CO2 injection all year round for the plants. This has a significant seasonal effect: consumption is highest in spring and lowest in winter.

We will see in this article how the CO2 can be consumed in a cultivation greenhouse with concrete examples. Indeed, there can be significant synergies between certain industries that produce CO2 and greenhouse growers who need it for their plants.

– Liquid CO2

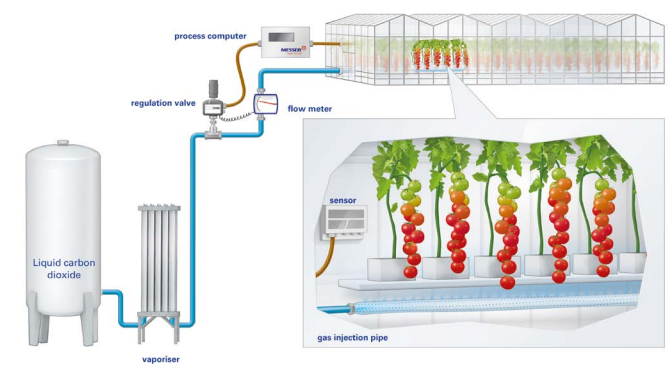

In the majority of large-scale greenhouse projects, CO2 is used in liquid form. The gas distribution system (pipes) is located as close as possible to the plants.

This type of technology is found notably in greenhouses for tomato, bell pepper and even cannabis production, which have high photosynthetic activity and CO2 requirements of up to 1200ppm (parts per million).

One of the main advantage of liquid CO2 is purity of product, no concerns about crop damage, nor heat or moisture production. Moreover, there is a better control of CO2 levels and more flexibility to introduce the CO2 within the plant canopy at any time. Uniform CO2 dosing plays a very important role in greenhouse production.

– CO2 gas (on-site combustion)

In the majority of large-scale greenhouse projects, CO2 is used in liquid form. The CO2 generated is then diffused directly into the growing areas. Nowadays, we see this in small and medium-sized greenhouse projects with gas furnaces.

One disadvantage when natural gas or propane is burned is that not only CO2 is produced. Indeed, incomplete combustion or contaminated fuels may cause plant damage and potential air contaminant for the workers. Combustion of fuels also generates moisture (= risks of fungus diseases), however, in case of propane the amount of moisture generated per kg of CO2 is slightly less than it is for natural gas.

For biomass heating systems, the challenge will be to filter the combustion gases to obtain the purest possible CO2. In addition, one of the challenges is the variability of biomass quality and therefore the consistent production of a “clean” CO2 for the plants.

Next step : is the CO2 generated by methanization usable?

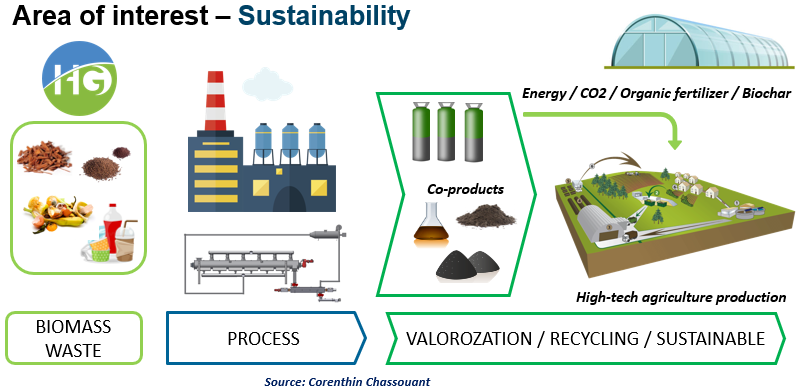

Methanization is popular in Northern Europe and is beginning to develop rapidly in France and the United States. This process allows the production of renewable energy (biomethane) and a solid digestate. This digestate, used as organic fertilizer, contributes to the closing of cycles and the maintenance of soil fertility.

During biomethane production, the gas purification process produces CO2. At present, this CO2 is not systematically recovered and therefore released into the atmosphere, contributing to global warming.

The market price of CO2 is currently highly variable, but one way of increasing its value would be to have methanization units as close as possible to production greenhouses, to reduce costs.

One of the main challenges will be to recover the CO2 generated and transport it at a cost that greenhouse growers can afford.

What’s more, the proximity of a cultivation greenhouse to a methanization unit opens up the possibility of other synergies, such as the valorization of heat and digestate in the cultivation substrates.

Conclusion

The CO2 is an essential parameter impacting the plant physiology and growth especially on the high photosynthesis crops. It can be injected directly from the local burner or indirectly through a liquid CO2 storage and diffusion system in the greenhouse.

The valorization of the CO2 offers new ways of industry synergies to mitigate atmospheric emissions and reduce the impact on climate change.

Source:

Atmospheric enrichment in greenhouses with carbon dioxide (.pdf)

Supplemental carbon dioxide in greenhouses:

https://www.ontario.ca/page/supplemental-carbon-dioxide-greenhouses#:~:text=The%20main%20advantages%20of%20using,by%20truck%20to%20the%20greenhouse.

Valorisation du CO2 de méthanisation (CTBM) French article :

https://atee.fr/system/files/2021-07/20200723_Guide_Valorisation_CO2_CTMB_modifVF.pdf