This post is also available in: ![]() English

English ![]() Français (French)

Français (French)

Introduction

Mid-tech poly greenhouse is still one of the best way to start producing quality fresh leafy greens and herbs all over the world. Indeed, it requires a moderate initial investment compare to a hi-tech greenhouse or indoor solution. In addition, once the system is up and running and showing increasing profitability, it will be possible to add more “high-tech” equipment to improve certain production and (pre/post) harvest aspects.

In a nutshell, the advantages are numerous such as the use of passive energy (sun light, ventilation…) and the large volume of the greenhouse to manage the climate while implementing an integrated pest management strategy. The energy consumption over the time will be also lower in most cases. In fact, operational cost control is one of the strongest performance indicators for crop managers.

BUT… even with this very efficient model, there can be mistakes at the beginning. In this article, we will see the main mistakes to avoid and how to get advice from industry experts.

More detail below about leafy greens cultivation in a greenhouse :

1/ Do not select a bad installation site

Not enough light, too cold or too hot (at night), too far from my market, too much energy expenses, bad water quality… the greenhouse installation site location is one of the most important factor for the success of your project.

If you have to clear the land before building your first greenhouse, you need to consider the soil quality (topographic analysis), drainage location (slope?), fresh water availability (and quality?), power supply access, possibility for expansion in the future on the same site ?…

Indeed, this can lead to huge additional expenses if not taken into account in your business plan.

Southern hemisphere

In the Southern hemisphere in tropical countries, in most cases, it is better to invest a bit more buying a highlands location (>700m elevation) with cooler nights, fresh water/electricity availability, enough space for future expansion… than a cheaper lowland location with warmer temperature, less ventilation… But you will have also to take consideration of the light amount (DLI) : Is my future site will get enough light ? It can be cloudy, foggy in some mountainous locations… Is the area exposed to higher pests and diseases risks ?

Regarding the transportation accessibility, can my future trucks come easily to collect the harvest and bring it to my customers ?

The lowland location can be closer to your customers (supermarkets, restaurants…) but if you have agronomic issues to grow due to the extreme climate conditions: it will affect negatively your yield and crops quality. Moreover, you will have to invest more in equipment and energy (cooling system for example) impacting your operational costs ↗ and profitability ↘.

“In Malaysia, one of the best grower leading the hydroponic lettuce market had invested 2 or 3x more per square meter on his new mid-tech greenhouses building a special steel structure on top of the mountain to benefit of the highlands climate conditions and market proximity closer to the big city Kuala Lumpur. The hydroponic system (NFT) was on top of it 25m above the ground !”

Corenthin (Félix) Chassouant

Northern Hemisphere

Under Nordic conditions, a big part of your operational cost will be linked to the heating system. You need to find the best location to be able to get a sufficient amount of light (Southern site exposed) with the possibility to build your insulated technical area on the Northern part of your greenhouse.

What is more, you will need to analyse the best source of energy available and which heating system will be the most efficient in your case: natural gaz, propane, biomass or even electrical furnaces ? It will also depend “of course” of the cost that you will pay at your location.

The proximity to your market (↘ logistic cost) and the land available for expansion are also important factors. Fresher your lettuce are with longer life span more appealing it will be for your clients and final consumer.

A horizontal one layer hydroponic system has the advantage to require less labor compare to open-field cultivation but you will need to be sure that you can find good workers close to your project location.

2/ Size well your first project

Before investing on larger greenhouse complex to grow more, the best advise is to start on a reasonable growing surface in the beginning in order to learn, do mistakes and have the opportunity to know better your future market.

Of course, if you want to sell to the supermarkets or larger companies you will have to produce a consistent good quantity of lettuce heads and herbs. In order to do this, a first block of greenhouses of ard 2000-3000 square meters (20 000 to 30 000 square feet) can be a very good start !

In case you have already more ” hydroponic cultivation” experience doing your own propagation using trays for example. More automated systems like Mobile Tray System (MTS) and Mobile Gullies System (MGS) for a first block of 5000 square meters (1/2 hectare) will be the best solutions to increase your crop density keeping a good cultivation consistancy using less workers.

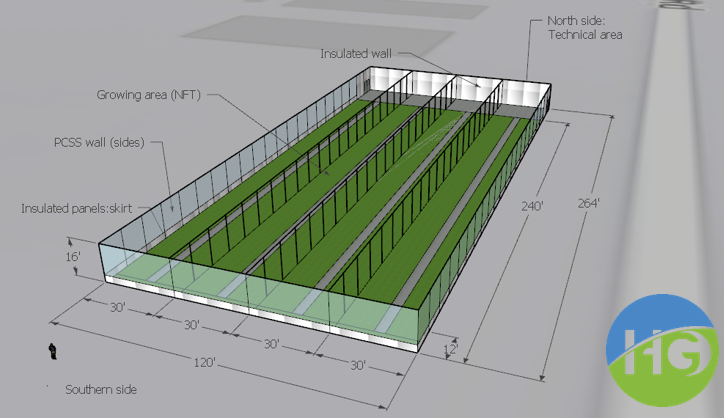

Exemple 1: Hydroponic greenhouse design for Northern countries

4 spans of 30′ wide x 264′ including the technical area on the Northern side.

The growing system in the exemple is a fixed gullies NFT with 2 rows of 12′ wide for hydroponic cultivation and a central pathway of 4′ on each span.

(imperial units below)

On the perimeter (side walls), you will be able to use insulated panel for the skirts and clear 8mm double-wall polycabonate (PCSS) to provide light and high insulation capacity. A double inflated polyethyelene roof (7,2 mil or 180 microns thick) will be the best covering material to get enough light (>85%), anti-drip / thermal treatment, high insulation capacity and possibility to have a larger motorized roof vent on top of each bay.

Closing the sides will avoid heat lose and pests and diseases potential contamination. In fact, the climate management will be a combination of passive ventilation (mid-roof) and active air circulation (using HAF or VAF) inside the growing area as we can see in the example below:

Enough height under gutter (> 14′) will create a large volume helping to control the temperature / humidity quick variation with a “buffer”

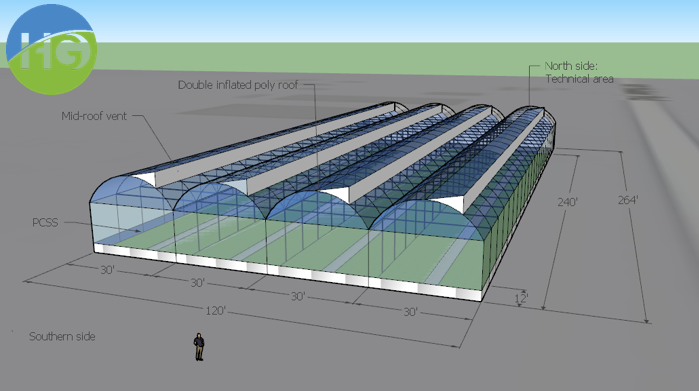

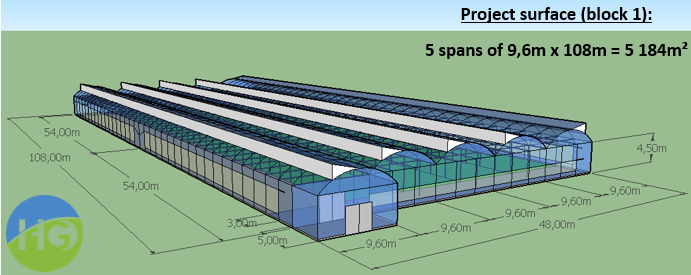

Exemple 2: Hydroponic greenhouse design for Southern countries

In warmer conditions, we will take more advantage of the passive ventilation (roof vents + side roll-ups) to ventilate draining out the excess humidity and heat especially in the Tropical regions.

(metric units below)

The sides of the greenhouse more exposed to pests (white flies, aphids, thrips…) can be covered with an insect proof netting but it will requier a good maintenance to clean it at least one every 6 months if not it will affect the net porosity cutting some of the ventilation %…

On the roofing, single layer poly can be an option but a double inflated poly is also a good alternative to keep your poly longer and have a better thermal insulation if you are using cooling or heating (at night) in your greenhouse. The most important will be to have a mid-roof vent on each bay to be able to renew the air passively.

Regarding the horizontal one layer hydroponic system, it can be fixed NFT gullies like we have seen before or a rack & pinions mobile gullies system (MGS) + mobile trays system (MTS) for the propagation section:

3) Do not over-equip your greenhouse at the beginning

In a greenhouse the equipment cost can be quite expensive especially the artificial lighting (LED), cooling system (chiller, high pressure fogging….), post-harvest automation…

The best recommandation after selecting the right installation site and growing surface size will be to start with the “standard equipment combo” to be able to reach your yield and quality targets. Then, later one you will be able to add new functionalities and equipment if needed.

You need to keep an eye every time on your business plan knowing the Return On Investment (ROI) of your facility.

Before adding expensive equipment, you need to be able to estimate if it will worth it : do I need LED or a CO2 injection system to increase my yield ? If yes, will the additional yield will cover the cost of my new investment ? How long will it take… ?

In the Southern hemisphere, a mid-tech greenhouse is the most appropriate approach. Indoor farming or fully equipped glasshouse will require much more capital investment and operational costs ↗.

To conclude this part, it is important to discuss about it with specialists to get the best advices.

4) Select the right varieties and seeds

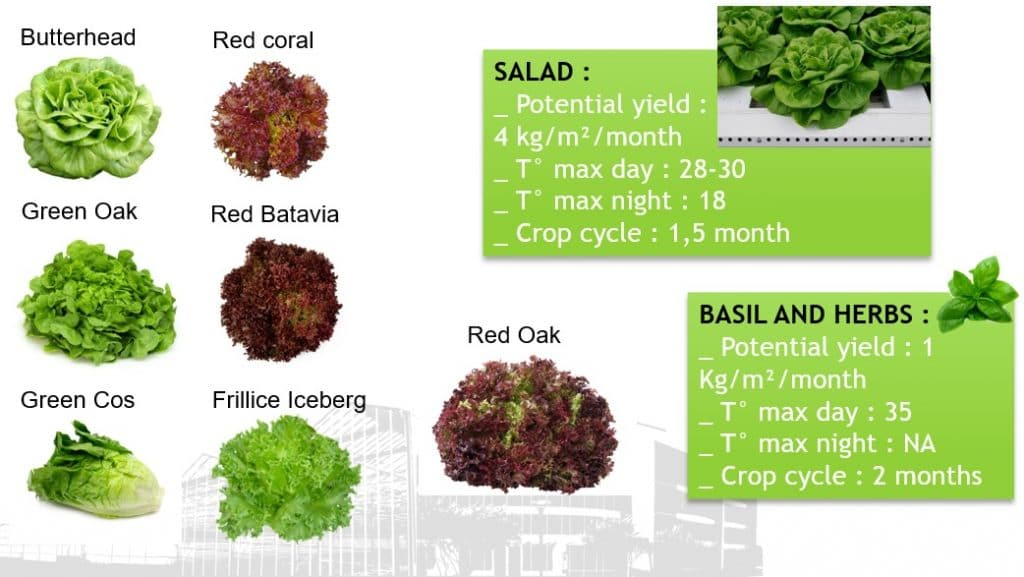

As we have seen in the first post introducing the leafy greens cultivation in a greenhouse, the crop variety and seeds selection is an important factor to consider if you want to be succesfull.

POTENTIAL CROPS (example) : Targeted crops yields and growing conditions

.

A complementary article about high-value alternative crops (grown hydroponically) in North-America:

5) Find the right head growers and advisors

You can have the best site and the best greenhouse (tool) but it is not sufficient! Indeed, the third keys of a successful hydroponic greenhouse is the head grower !

The head grower will be your everyday support anticipating on potential issue adjusting your ferti-irrigation and climate control set-up when it will be necessary. Hydroponic leafy greens cultivation can look an easy system to run, it is not.

In fact, it is a much more complex system where you will need a constant monitoring and control on many environment (water, workers…) and climate parameters to avoid the failure.

Moreover, you will also need to work with strong companies supporting you before/during and after the sale process to follow your progress, give the best service and support you all year round.

Do not hesitate to contact me if you are looking for more information and support for your future hydroponic project !

(Bonus personal photos)

Source:

Personal experiences and pictures from Corenthin (Félix) Chassouant (author)

[…] 5 mistakes to avoid – Hydroponic greenhouse for leafy greens […]

[…] 5 mistakes to avoid – Hydroponic greenhouse for leafy greens […]